Continuous Carbonization Furnace and Charcoal Production: Efficient Solutions for Industrial Charcoal Manufacturing

Charcoal remains one of the most versatile and widely used fuel sources worldwide. From cooking and heating to industrial applications and biochar production, high-quality charcoal plays a critical role in many sectors. Modern manufacturing technologies, such as the continuous carbonization furnace and complete charcoal production lines, have revolutionized charcoal production by increasing efficiency, consistency, and output. These innovations provide industrial-scale producers with reliable solutions for meeting growing market demand.

This article explores how continuous carbonization furnaces and charcoal production systems work, their advantages, and why they are essential for modern charcoal manufacturing.

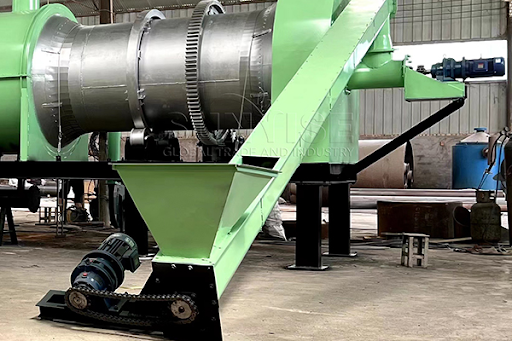

What Is a Continuous Carbonization Furnace?

A continuous carbonization furnace is industrial equipment designed for the uninterrupted production of charcoal from biomass. Unlike traditional batch kilns, which require stopping and restarting between batches, continuous furnaces allow raw materials to be processed continuously, significantly improving efficiency.

These furnaces work by heating biomass such as wood, bamboo, coconut shells, or agricultural residues in a low-oxygen environment. During the process, volatile gases are released and can be recycled as fuel, making the system highly energy-efficient. The continuous operation ensures uniform continuous carbonization furnace resulting in high-quality charcoal with consistent density, calorific value, and low ash content.

Key Features of Continuous Carbonization Furnaces

- High Productivity

Continuous operation enables industrial-scale output without downtime. - Energy Efficiency

The furnace recycles pyrolysis gases to reduce external fuel consumption. - Automation

Modern furnaces incorporate temperature control, conveyors, and gas recovery systems for minimal labor requirements. - Environmental Protection

Controlled carbonization reduces harmful emissions compared to traditional methods. - Consistent Quality

Uniform heat distribution ensures that all biomass is evenly carbonized.

Industrial producers looking to scale up their charcoal operations often turn to continuous carbonization furnaces as the backbone of their production lines.

Charcoal Production Lines: Comprehensive Solutions

While a continuous furnace is the heart of the carbonization process, a complete charcoal production line encompasses the entire workflow from raw biomass to finished, market-ready charcoal. A production line typically includes several integrated components:

- Raw Material Preparation

Biomass is crushed and sized for efficient processing. - Drying System

Moisture content is reduced to optimize carbonization. - Carbonization Unit

Continuous furnaces or batch kilns convert biomass into charcoal. - Cooling and Screening

Finished charcoal is cooled and sorted by size. - Packaging

Charcoal is bagged or packaged for retail or industrial distribution.

A fully integrated charcoal production line ensures seamless operations, minimal manual labor, and high-quality output suitable for commercial sales.

Advantages of Modern Charcoal Production Systems

1. Enhanced Efficiency

Modern production systems significantly reduce the time and labor required for charcoal manufacturing. Continuous carbonization furnaces, in particular, allow for uninterrupted operation, producing more charcoal per hour compared to traditional batch methods.

2. Cost Savings

Recycling pyrolysis gases and automating critical steps lowers energy and labor costs, reducing overall production expenses.

3. Superior Product Quality

Consistent temperature control and uniform carbonization result in charcoal with uniform size, density, and calorific value — crucial for both commercial and industrial applications.

4. Environmental Sustainability

Advanced furnaces minimize smoke, dust, and harmful emissions. Utilizing agricultural residues as biomass feedstock also promotes sustainable resource use.

5. Scalability

Production lines can be customized for small, medium, or large-scale operations, making them suitable for businesses of all sizes.

Applications of Charcoal

Charcoal produced using continuous carbonization furnaces and full production lines has multiple applications:

- Residential Cooking and Heating

Charcoal briquettes for stoves and grills. - Industrial Fuel

Metallurgical and chemical industries rely on charcoal for energy and processing. - Agricultural Use

Biochar improves soil fertility and water retention. - Filtration and Purification

Activated charcoal is used in water and air purification systems.

The versatility of charcoal ensures a steady market demand across sectors.

Choosing the Right Charcoal Production System

When investing in a continuous carbonization furnace or complete charcoal production line, several factors should be considered:

- Raw Material Availability

Determine the type and quantity of biomass you will use. - Production Capacity

Evaluate your expected output to select a system that matches your business scale. - Automation Level

Systems with higher automation reduce labor costs and improve efficiency. - Environmental Compliance

Ensure the furnace and production line meet local environmental regulations. - Supplier Support

Choose manufacturers who provide installation, training, and after-sales service.

Conclusion

In modern charcoal manufacturing, combining a continuous carbonization furnace with a complete charcoal production line ensures efficiency, quality, and profitability. These technologies allow producers to process biomass sustainably, reduce costs, and deliver consistent, high-quality charcoal for a wide range of applications. Whether for commercial, industrial, or agricultural use, investing in advanced charcoal production systems is a smart, future-proof decision for businesses seeking to scale and compete in a growing market.

By adopting modern furnaces and integrated production lines, manufacturers can not only meet rising demand but also operate sustainably, efficiently, and profitably — securing a competitive advantage in the global charcoal industry.